| Residential & Commercial Polished Concrete | |

|---|---|

| Residential Polished Concrete Floors Austin | Refined concrete floors perfect for modern homes and interiors. |

| Commercial Polished Concrete Floors Austin Texas | Durable and clean concrete flooring for retail, warehouses, and offices. |

| Polished Concrete Patio Austin TX | Weather-resistant polished concrete surfaces for outdoor living spaces. |

| Polished Concrete Cost | Affordable pricing options based on square footage and finish level. |

| Polished Concrete Cost Near Me | Local price estimates for polished concrete floors in your area. |

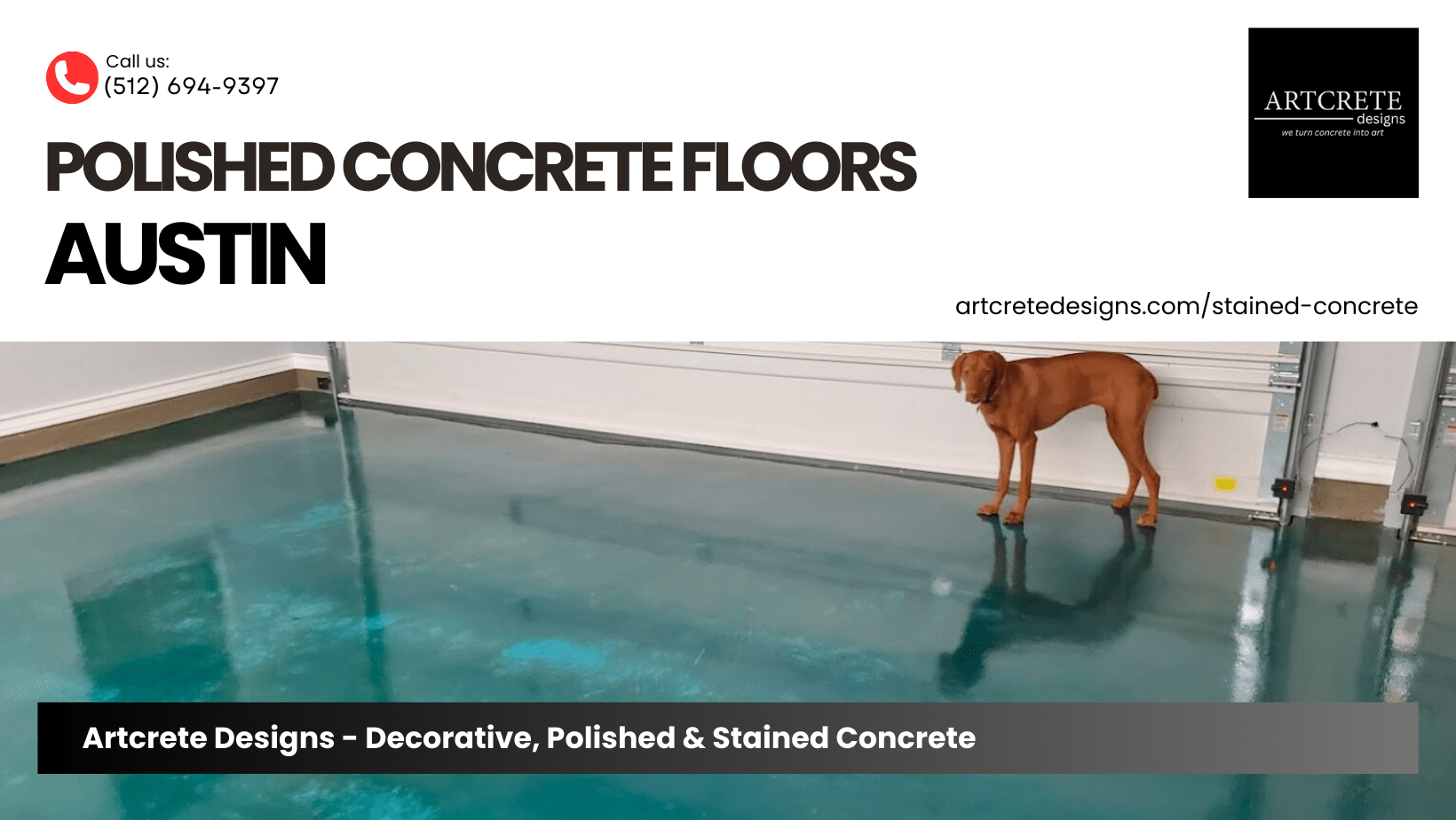

Artcrete Designs – Elevate Your Space with Polished Concrete

Polished concrete brings sleek elegance and exceptional performance to any space—and at Artcrete Designs, we’re the experts Austin trusts for custom-crafted concrete floors. Whether it’s for a stylish home interior or a high-traffic commercial setting, our polished concrete solutions deliver lasting beauty and unmatched durability.

Our team refines raw concrete with advanced polishing systems that reveal a smooth, radiant finish. You can choose from various levels of gloss to match your style—from soft sheen to high-gloss brilliance—giving your space a fresh, modern appeal.

Durable, easy to clean, and eco-friendly, polished concrete floors stand up to stains, water, and wear without fading or cracking. They’re also excellent for indoor air quality, as they don’t harbor dust, mold, or allergens like traditional flooring options.

Each polished floor we create is one-of-a-kind. We work with you through every step—from consultation to final polish—to ensure your surface fits your functional needs and aesthetic vision.

Want a floor that’s as stunning as it is strong? Contact Artcrete Designs today and discover the power of polished concrete.

Radiant heating systems are an efficient way to heat a space evenly and comfortably. When it comes to polished concrete floors, they are not only aesthetically pleasing but also excellent conductors of heat. This characteristic makes polished concrete an ideal partner for radiant heating systems. The thermal mass of the concrete absorbs the heat from the system and then radiates it into the room, providing consistent warmth underfoot.

Incorporating radiant heating within a polished concrete floor requires planning and precision. The installation typically involves embedding hydronic tubes or electric mats into the concrete before it is poured or placed directly over an existing slab before polishing. Professional installers can ensure that the radiant heating elements are distributed evenly to avoid cold spots and optimize energy efficiency. Once installed, the system can be fine-tuned to achieve the desired temperature settings, ensuring comfort throughout the deck area.

Radiant heating paired with polished concrete floors is not just about comfort; it's also about energy efficiency. By using the dense nature of concrete to store and slowly release heat, this combination reduces the need for frequent cycling of a home's heating system, which can lead to lower utility bills. However, there are initial costs involved in installing such a system—the cost of materials and labor for installing radiant heating can vary depending on several factors including square footage and type of system selected (electric vs hydronic).

A significant advantage of combining radiant heating with polished concrete floors is low maintenance requirements alongside durability. Polished concrete is known for its long lifespan and resistance to wear, making it a smart choice for high-traffic areas like decks. Additionally, since there are no vents or ducts associated with radiant floor heating, there's less need for cleaning and maintenance related to air quality concerns. With proper care, both your polished concrete flooring and radiant heating system should provide many years of reliable use.

Polished concrete flooring is a popular choice in various settings, from residential to commercial spaces, due to its durability and sleek aesthetic. The process involves grinding down the surface of existing concrete to achieve a smooth finish. However, before opting for this type of flooring, it’s essential to consider the required thickness to ensure longevity and performance.

The minimum thickness for a polished concrete floor typically depends on the setting and expected traffic levels. Generally, for residential applications, a thickness of at least 100mm is recommended for new slabs. In commercial or industrial environments with higher traffic, thicker slabs ranging from 125mm to 150mm are preferable. These measurements provide enough depth for multiple grindings and polishings without compromising structural integrity.

When dealing with existing concrete slabs, the focus shifts to assessing current conditions rather than predefined specifications. If the slab is already in place and exhibits sufficient quality and stability, then polishing can usually proceed without adding additional layers. Professionals will evaluate factors such as cracks, wear patterns, and overall flatness before deciding if the concrete's thickness is adequate for polishing.

Regardless of whether you're working with new or existing floors, maintaining proper floor integrity is crucial for polished concrete success. This includes ensuring that there's uniform thickness across the entire surface area and that any necessary repairs are undertaken prior to beginning the polishing process. Adequate structural support beneath the slab should also be verified to prevent future cracking or damage that could compromise not only aesthetics but also safety.

In conclusion, while roof-related considerations do not directly impact polished concrete floors' thickness requirements, understanding these guidelines ensures your polished floor remains resilient against wear and tear over time.

Mechanically polished concrete is ground and polished to a high sheen, whereas grind-and-seal involves grinding the surface, then applying a sealer on top. The former provides a more durable and long-lasting finish.

Concrete should be at least 4 inches thick to ensure durability and the ability to withstand polishing.

Polished concrete requires less maintenance than tile or hardwood. It'sresistant to stains, scratches, and does not require waxing or sealing like hardwood floors.

Yes, they are eco-friendly because they use the existing concrete slab and require minimal chemicals, and the process does not involve harmful substances.

Yes, polished concrete can be used outdoors, but it should be sealed properly to prevent water absorption and maintain the finish.